Technical • 08 Jan 2026

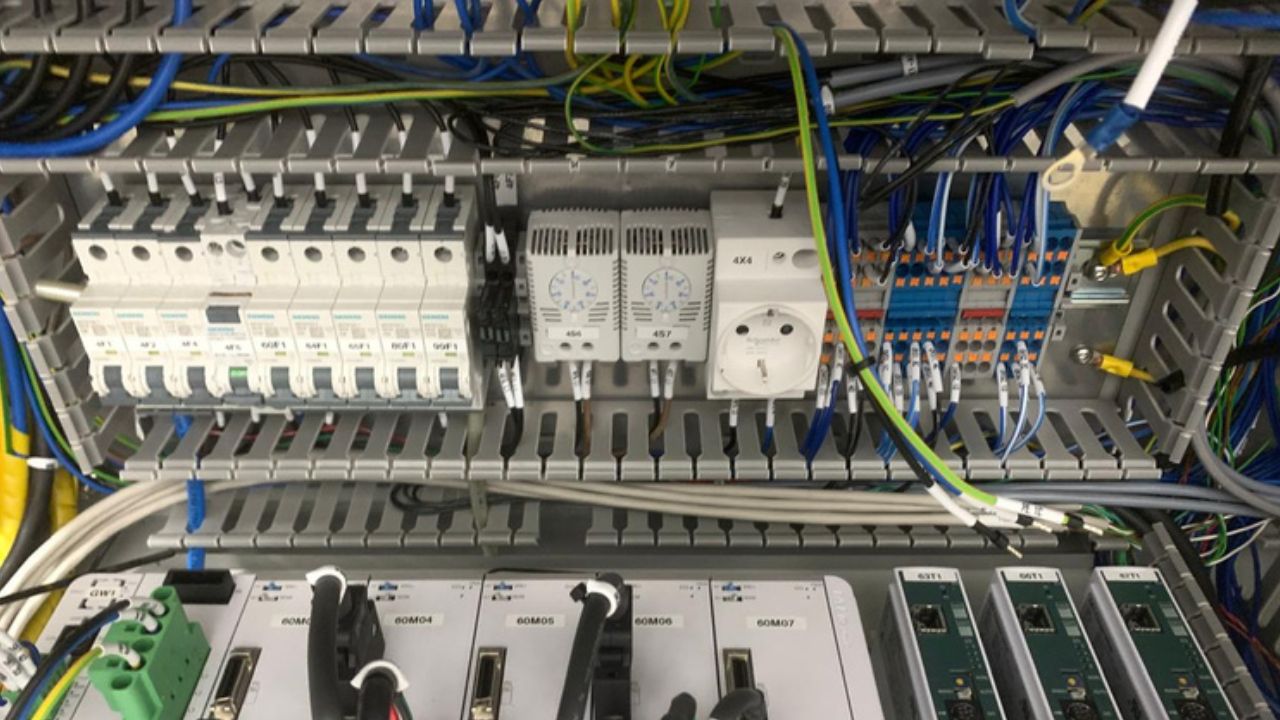

Understanding Industrial PLC Control Panel Components and Their Functions

An industrial PLC (Programmable Logic Controller) control panel is the core of an automation system. It houses various electrical and electronic components that work together to control machines and industrial processes reliably and safely.

Main Components and Their Functions

1. PLC (Programmable Logic Controller)

The PLC acts as the brain of the automation system. It receives input signals from sensors, processes the data according to a programmed logic, and sends output signals to actuators such as motors, valves, or relays.

2. Power Supply Unit (PSU)

The power supply converts AC voltage into regulated DC voltage, commonly 24VDC, which is required to power the PLC, sensors, and control circuits.

3. Circuit Breakers (MCB/MCCB)

Miniature Circuit Breakers protect the system from overloads and short circuits. They ensure the safety of both equipment and personnel.

4. Input and Output Modules (I/O Modules)

Digital Inputs (DI): Receive signals from switches, sensors, and push buttons.

Digital Outputs (DO): Control devices such as relays, contactors, and indicator lamps.

Analog Inputs/Outputs (AI/AO): Handle variable signals like temperature, pressure, or flow.

5. Terminal Blocks

Terminal blocks provide organized and secure connections for field wiring, simplifying installation and maintenance.

6. Relays and Contactors

These components act as electrically operated switches, allowing low-power control signals to operate high-power devices.

7. Wiring and Cable Management

Neatly arranged wiring improves reliability, reduces troubleshooting time, and ensures compliance with industrial standards.